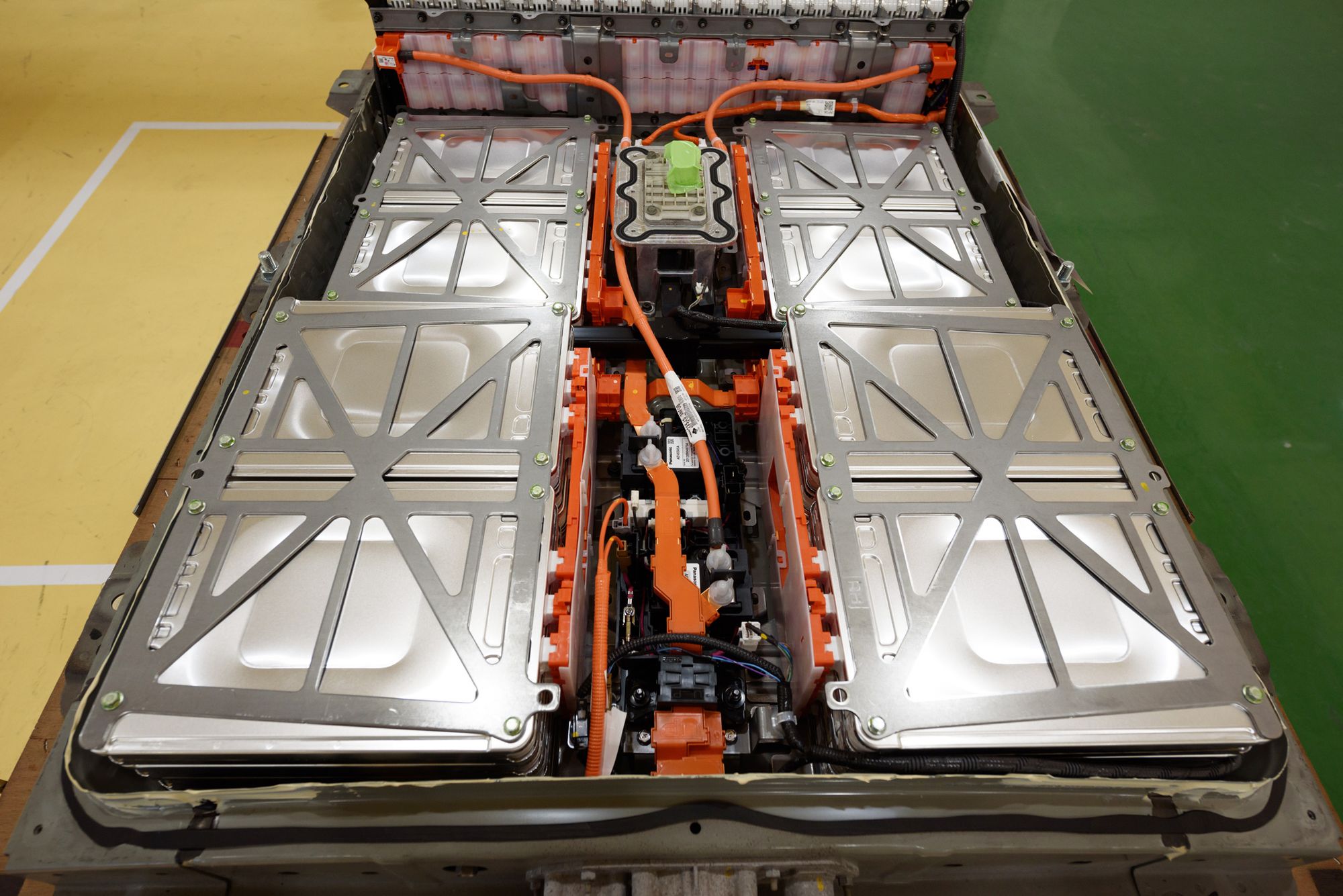

Raw materials for Electric vehicle battery.

Electric vehicles are becoming more popular, with governments even encouraging their use through legislation. In the recent concluded Africa Climate Summit 2023 (ACS23) we saw president of The Republic of Kenya driving an electric car and his motorcade being electric motorbikes and vehicles as well.

Electric vehicles are becoming more popular, with governments even encouraging their use through legislation. In the recently concluded Africa Climate Summit 2023 (ACS23) we saw the president of The Republic of Kenya driving an electric car and his motorcade being electric motorbikes and vehicles as well. Drawing from this endorsement of electric rides by the president we have seen most people embracing electric vehicles and going ahead to pre-order electric vehicles from the same company that the president used their car, Air EV Yetu. The price of one Air EV Yetu ranges from 1.4- 1.7 million Kenya shilling which is 9,524 dollars on the lowest.

It is equally important to note that the majority of the raw materials used to manufacture electric vehicle batteries come from Africa specifically Congo. However, there are risk factors that come as a result of the mining such as minors being exposed to mines. The human rights defenders have challenged this because most of the children are not able to go to school as they have to work to fend for their families. Equally, the mines cause pollution which leads to health-related issues.

With all the challenges caused, it is important not to forget that electric vehicles are important in helping curb the global warming crisis that we are experiencing as a result [of climate change which is a result of pollution from the internal combustion engines commonly known as ICEs. According to UNEP, 90 percent of urban air pollution in rapidly growing cities such as Nairobi, Kenya comes from motor vehicles. Vehicle pollution is a mixture of particulate matter (particles) such as carbon monoxide, Sulphur oxides, nitrogen oxides, and a wide range of volatile organic compounds.

The most essential component of electric vehicle technology is the battery. Modern electric vehicles mainly have lithium-ion and lithium polymer batteries due to the relatively higher energy density compared to weight.

The major materials required in lithium-ion batteries are the chemical components lithium, manganese, cobalt, graphite, steel, and nickel. These components all have different functions in the typical electric vehicle battery that contribute to improved performance.

i) Lithium

Lithium-ion batteries internally move lithium ions from one layer, known as the anode, to another, known as the cathode, to generate power. Lithium-ion batters are more convenient to use in electric vehicles because compared to lead-acid or nickel-metal hydride batteries, lithium-ion batteries offer higher energy densities, making it possible to reduce battery size while maintaining storage capacity.

ii)Manganese

Safety is the main reason manganese is used in lithium-ion batteries. Because of its increased energy density properties and reputation for stability, manganese is known to increase capacity and improve driving range. Additionally, manganese reduces the combustibility of electric vehicle batteries, which is problematic with lithium-ion batteries that contain cobalt.

iii) Cobalt

Cobalt helps extend the life of batteries, which manufacturers typically guarantee for eight to ten years, and it also guarantees that cathodes do not quickly overheat or catch fire.

iv) Graphite

Graphite plays a critical role in the anode that stores lithium ions. Most commercially available lithium-ion batteries employ graphite due to its good cycle stability and energy density.

v) Steel

Steel provides the best balance of strength, mass reduction, performance, cost, and environmental impact. Steel is the preferred material for today's automobiles and will continue to be the preferred material for vehicles in the future.

vi) Nickel

Electric vehicle batteries contain nickel, jet engine turbines employ nickel alloys, and passenger trains and subways use stainless steel that contains nickel. Materials containing nickel provide improved corrosion resistance as well as dependable and effective electrical and spark systems.