The EV battery revolution needs sustainable materials.

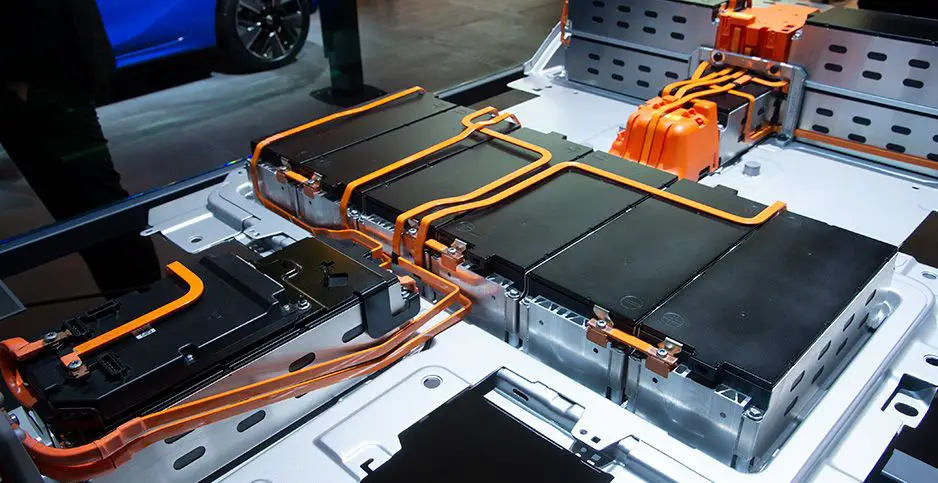

For the world to be fully electrified, there is a need to produce huge amounts of lithium-ion batteries. However, for this to happen we need new sources and technology to cushion this, they include extract and process battery materials such as lithium, cobalt, and nickel.

For the world to be fully electrified, there is a need to produce huge amounts of lithium-ion batteries. However, for this to happen we need new sources and technology to cushion this, they include extract and process battery materials such as lithium, cobalt, and nickel.

These materials are extracted from the ground. In most cases mining these materials go against the humanitarian, such as cobalt has been at loggerheads with the people of Congo because its the children who mine it and hence put their lives at risk of contracting respiratory diseases, school drop-out among others. Also, environmental reasons surround lithium when it evaporates during extraction. There are conversations from the battery giants, technology startups, EV makers, investors, and policymakers on how to find sustainable sources.

For minerals to produce a single 1,000 lb EV battery involves mining, moving, and processing 500,000 lbs of raw materials. As the electric vehicle industry expands, we need 6-10 times the amount of lithium, nickel, cobalt, graphite, and manganese being used in the world currently. 75% of nickel are found in few countries such as Australia, Indonesia, South Africa, Russia, and Canada. Engineers are working hard to replace cobalt with Nickel in electric cars, therefore there might be more pressure on where and how to find Nickel.

According to the CEO of Kobold metals, Kurt House, A major component of the renewable energy revolution is how to get the materials needed to do it. KoBold Metals is a startup that is building and applying machine learning and advanced scientific techniques for battery mineral exploration. The company is funded by investors Breakthrough Energy Ventures, Andreessen Horowitz, and Norwegian state oil company Equinor.

KoBold boss estimates by 2050 the world will be fully electrified. For this to happen the world will need approximately $4 trillion worth of new battery materials. House emphasizes that the materials are had to get and no clear place where to find them. Once a sustainable battery is found and extracted, it will be a lifelong solution to clean transportation. Extracting fuels are extracted from the ground and burned. It's hard to get carbon back in a thermodynamic way.

The startup company is finding places where they can mine cobalt, currently it's in Congo, they also investigating if they can mine it in Northern Quebec in Canada. The company is using technology to find sustainable battery materials Another new player is Lilac Solutions, which has developed a more efficient and faster process to extract lithium from underground brines. Meanwhile, Redwood Materials is a startup developed by former Tesla Chief Technology Officer JB Straubel that is taking scrap metal from EV battery production and using that for the raw materials of other EV batteries.

Apart from the startup companies, big battery companies are eager for alternatives to the hard to mine materials such as cobalt. Tesla and Apple plan to do away with cobalt in their batteries, mainly because the material is expensive to mine also the availability of cobalt, as we know it is only concentrated in one place(Congo) and the environmental challenges associated with the mining of cobalt( Child labor, respiratory diseases among others)

Mining giants, battery makers, auto manufacturers, and energy companies will have to create a new framework to source, extract and process battery materials sustainably and then take back older EV batteries to both reuse and recycle them. And a lot of financing will be required to help set these systems up.

Source: Katie.F (2021) The electric revolution needs a sustainable battery material.