The Journey of an EV Battery: From Factory to Rebirth.

Electric vehicles (EVs) are making headlines for their positive environmental impact and advancing technology, but the true heart of an EV is the battery.

Electric vehicles (EVs) are making headlines for their positive environmental impact and advancing technology, but the true heart of an EV is the battery.

Behind every mile traveled, every smooth acceleration, and every quiet drive lies a fascinating journey that the battery undertakes.

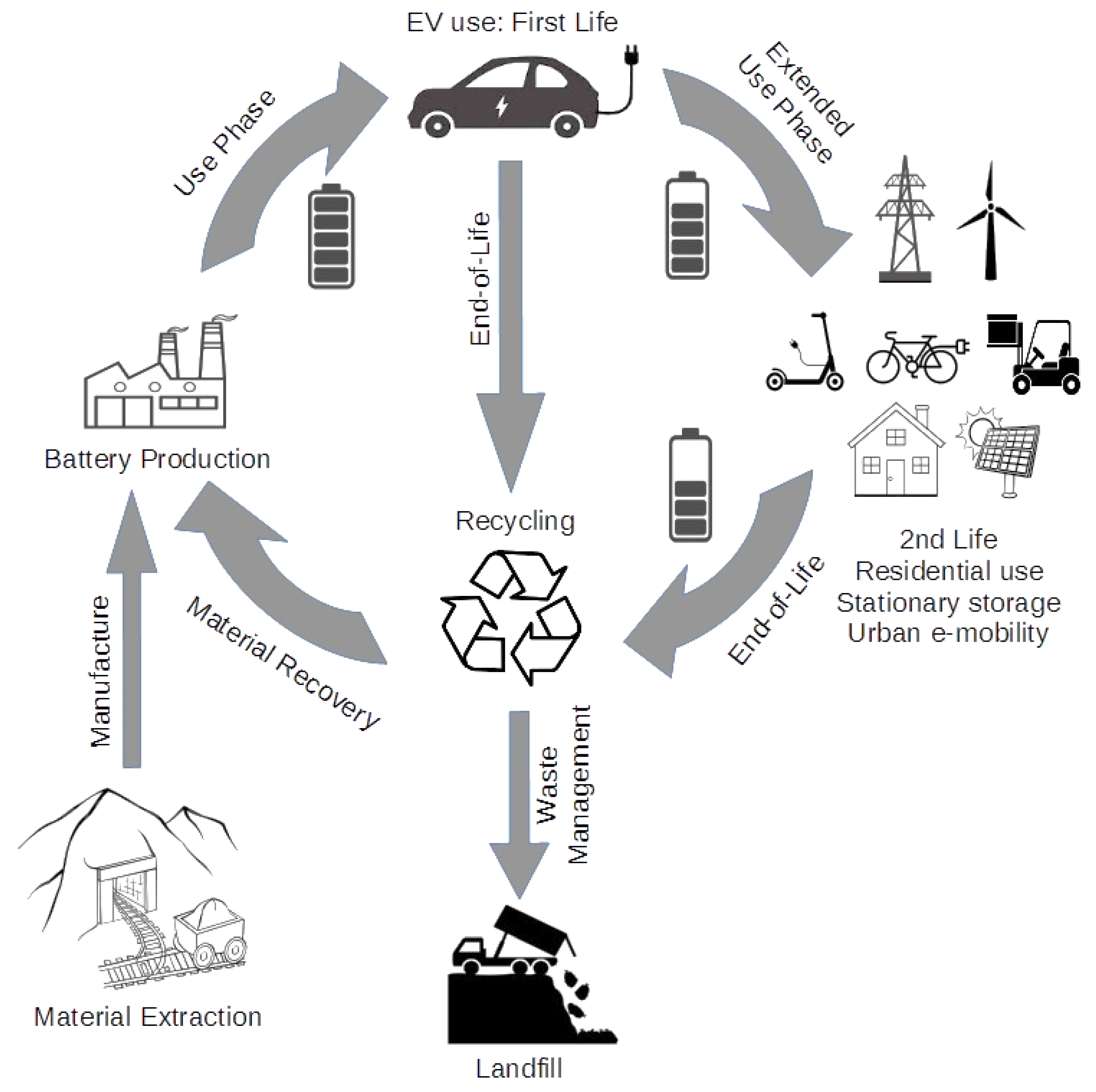

We’ll explore the complete lifecycle of an EV battery, from its origins as raw materials, through its active life powering a vehicle, to its rebirth in new applications, where it continues to support sustainable energy.

1. The Beginnings: Raw Materials Extraction

The journey of an EV battery starts far from the factory floor, in the mines and processing facilities where raw materials are sourced.

The essential materials for lithium-ion batteries—such as lithium, cobalt, nickel, and manganese—are extracted from various locations around the world.

- Lithium: Often mined from salt flats in South America or extracted from hard rock deposits in Australia.

- Cobalt: Sourced mainly from the Democratic Republic of the Congo, where ethical concerns have led to a focus on sourcing alternatives and reducing cobalt dependence.

- Nickel and Manganese: Commonly mined across Australia, Russia, Canada, and Indonesia.

The mining and processing of these materials are energy-intensive and have environmental impacts, which is why EV manufacturers are increasingly focusing on responsible sourcing.

Some manufacturers are now investing in alternatives to reduce reliance on certain materials, such as cobalt-free batteries.

2. Manufacturing: The Assembly of a Battery Pack

Once the raw materials are refined, they are shipped to battery manufacturing facilities.

In these state-of-the-art factories, the materials are transformed into battery cells through a delicate process involving electrode production, electrolyte filling, and cell assembly.

This is where cells are created, each storing energy in a compact form.

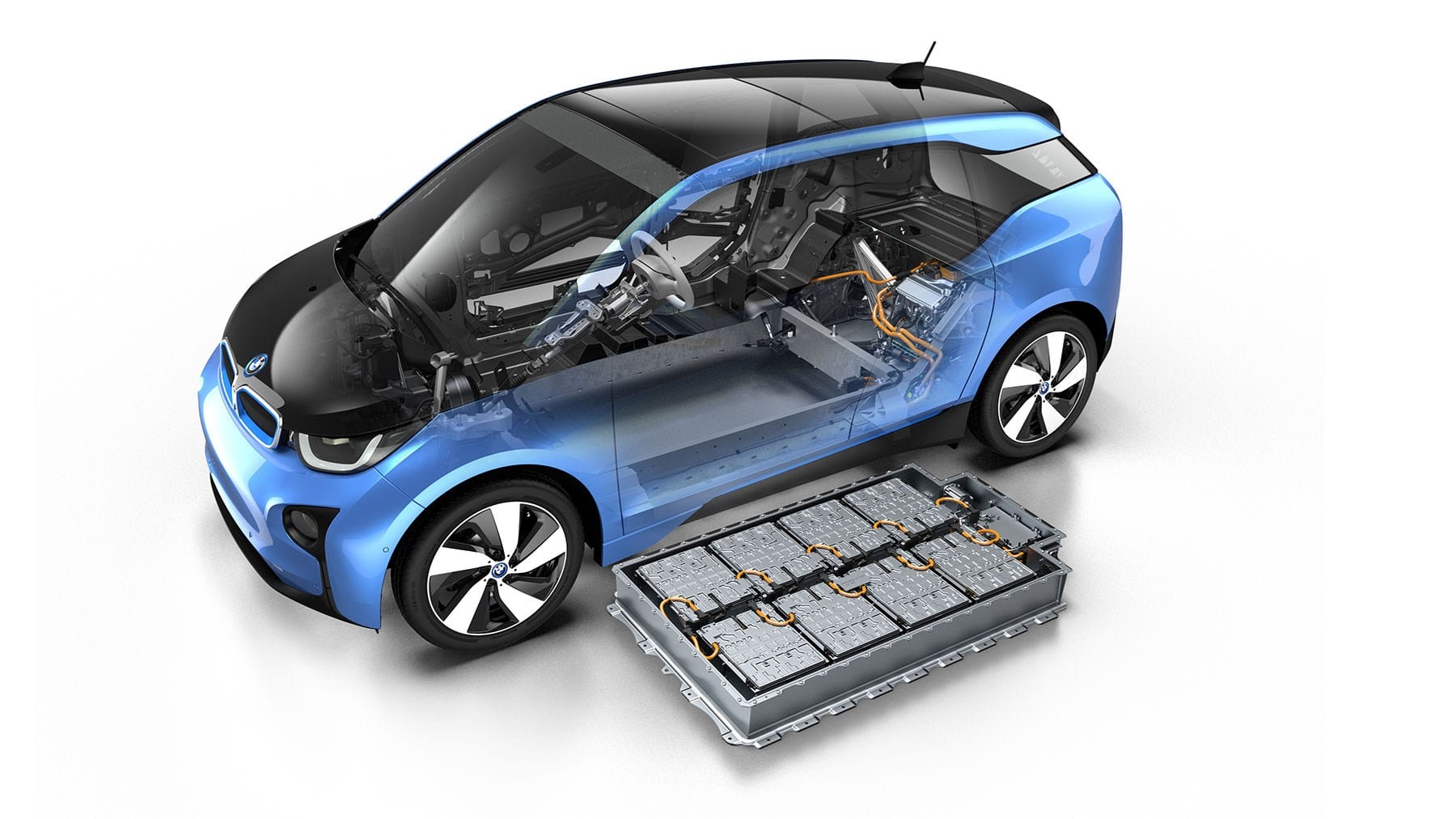

These cells are then organized into modules, which are arranged into battery packs.

Each EV battery pack is carefully engineered to ensure optimal performance, energy density, and safety.

A single battery pack contains hundreds, sometimes thousands, of cells, allowing it to power an EV for long ranges.

Factories dedicated to producing EV batteries are increasingly designed to reduce environmental impact, with many powered by renewable energy sources like solar or wind.

3. First Life: Powering the Electric Vehicle

The newly assembled battery packs are then sent to EV manufacturers, where they’re installed in vehicles.

This marks the beginning of the battery’s “first life” as it powers an EV on the road.

During this first life, the battery enables the EV’s primary functions: acceleration, braking, and energy recuperation through regenerative braking.

An EV battery’s performance is a balancing act of chemistry and software, with onboard systems continually optimizing the power output to ensure maximum efficiency and longevity.

EV batteries typically last between 8 to 15 years, depending on the driving habits, climate, and charging patterns.

Many manufacturers guarantee their batteries for at least eight years, as lithium-ion technology has proven durable and long-lasting.

However, as the battery ages, its capacity gradually decreases, reducing its maximum range.

Eventually, it reaches a point where it no longer meets the performance needs of an EV—usually around 70-80% of its original capacity.

4. Second Life: Repurposing for Energy Storage

When an EV battery is no longer efficient enough for vehicle use, it enters its “second life.” Instead of being discarded, batteries with diminished capacity can be repurposed for stationary energy storage systems.

These systems play a crucial role in the transition to renewable energy by storing excess power generated from solar panels and wind turbines, releasing it when needed.

The demand for these stationary storage solutions is on the rise as they are increasingly used to stabilize power grids and support renewable energy adoption.

Companies are developing “second-life battery” applications, turning old EV batteries into energy storage solutions for homes, businesses, and even entire communities. For example:

- Home Energy Storage: Old EV batteries can be used to store solar energy in residential homes, allowing homeowners to rely less on the grid and save on energy costs.

- Grid-Level Storage: Utilities use these second-life batteries to store energy on a larger scale, balancing the grid during peak hours or compensating for fluctuations in renewable energy generation.

By repurposing batteries in this way, the useful life of an EV battery is extended by many years, reducing waste and further contributing to a sustainable energy system.

5. The Final Chapter: Recycling and Resource Recovery

Eventually, even a repurposed battery reaches the end of its useful life. However, instead of ending up in a landfill, it enters its final chapter: recycling.

Advanced recycling facilities carefully dismantle used batteries, recovering valuable materials like lithium, cobalt, nickel, and copper.

Recycling an EV battery is a meticulous process:

- Collection and Dismantling: Batteries are collected and manually disassembled.

- Shredding and Separation: Components are shredded to separate metals, plastics, and chemicals.

- Chemical Recovery: Through processes like hydrometallurgy or pyrometallurgy, key materials are extracted, purified, and returned to the supply chain.

Recycling not only reduces the need for new raw material extraction but also minimizes environmental impact, cutting down on waste and reducing reliance on finite resources.

Companies worldwide are now investing in battery recycling facilities, with some EV manufacturers even creating closed-loop recycling systems, where materials from old batteries are used to create new ones.

6. Toward a Circular Economy

The journey of an EV battery from factory to rebirth highlights the potential for a circular economy—an economic model where resources are reused and recycled to create a closed-loop system.

This approach minimizes waste and environmental impact, creating a more sustainable supply chain.

Efforts to improve every stage of the EV battery lifecycle are rapidly evolving.

Companies are developing solid-state batteries with longer lifespans and fewer toxic materials.

Research is ongoing to increase the efficiency of second-life applications and improve recycling methods.

As technology advances, EV batteries are likely to become even more sustainable, making electric vehicles a cleaner and greener choice.

Conclusion

An EV battery’s journey is a testament to innovation, resilience, and commitment to sustainability.

From raw materials deep within the Earth to an active life on the road, a repurposed second life, and finally to recycling and renewal, the battery’s life is part of a greater ecosystem.

As we move toward a cleaner energy future, each stage of this journey will continue to evolve, setting a path for more efficient and sustainable battery technologies.

The next time you see an EV on the road, remember: its battery is more than just a power source—it’s a symbol of progress, persistence, and the future of clean energy.