The Most Critical Area for the E-Mobility Workforce: Skilled Technical Expertise in Battery Technology.

As the world pivots towards electric mobility (e-mobility) to reduce carbon emissions and tackle climate change, the most critical area for the e-mobility workforce lies in battery technology and energy storage systems.

As the world pivots towards electric mobility (e-mobility) to reduce carbon emissions and tackle climate change, the most critical area for the e-mobility workforce lies in battery technology and energy storage systems.

The transition from fossil-fuel-powered vehicles to electric vehicles (EVs) hinges on advancements in battery performance, cost, durability, and sustainability.

This demand for expertise in battery technology is transforming the workforce landscape, requiring professionals with specialized technical knowledge and hands-on experience in key areas of energy storage.

Read: How Electric Car Batteries Work

Why Battery Technology is the Core of E-Mobility

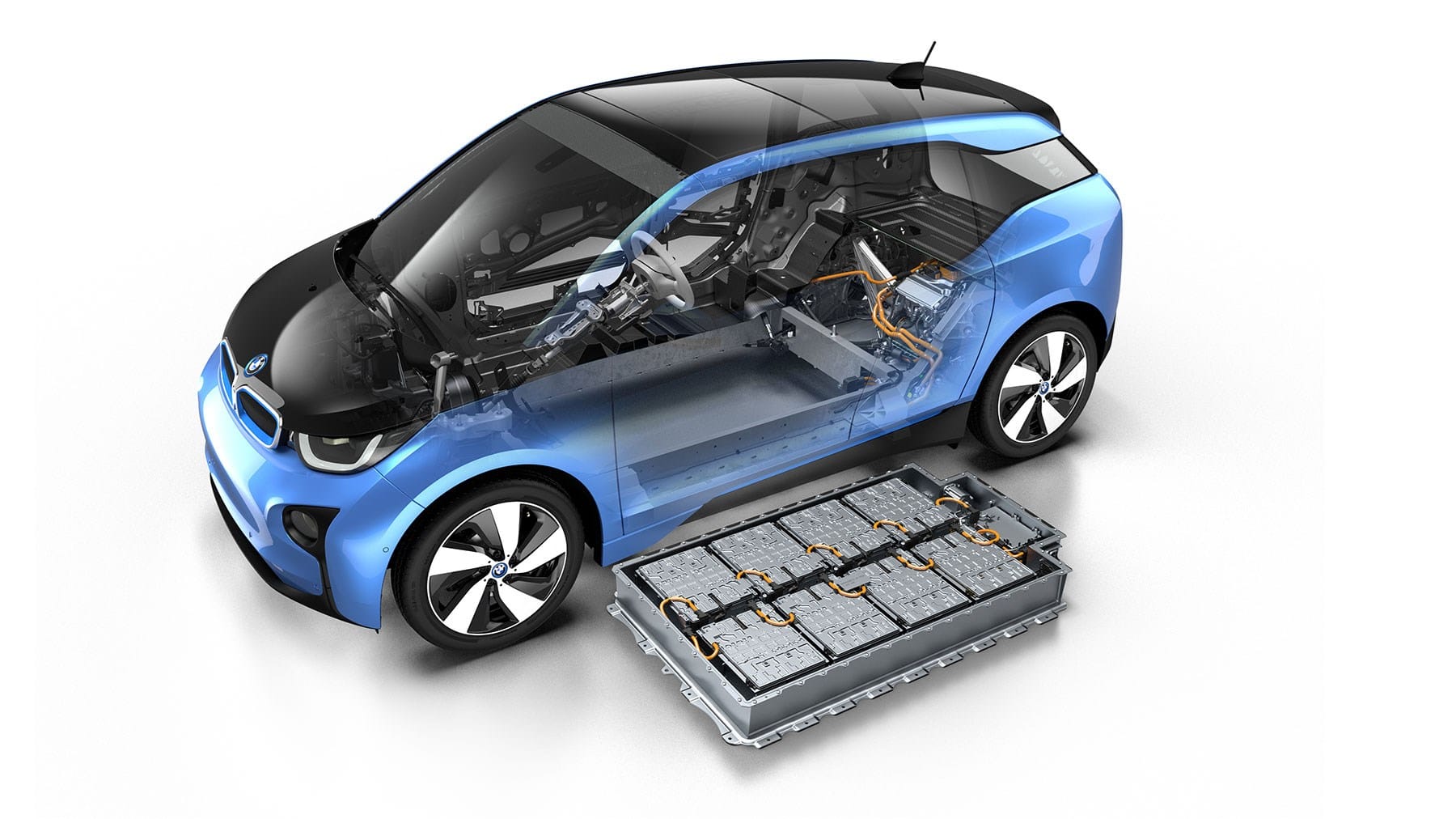

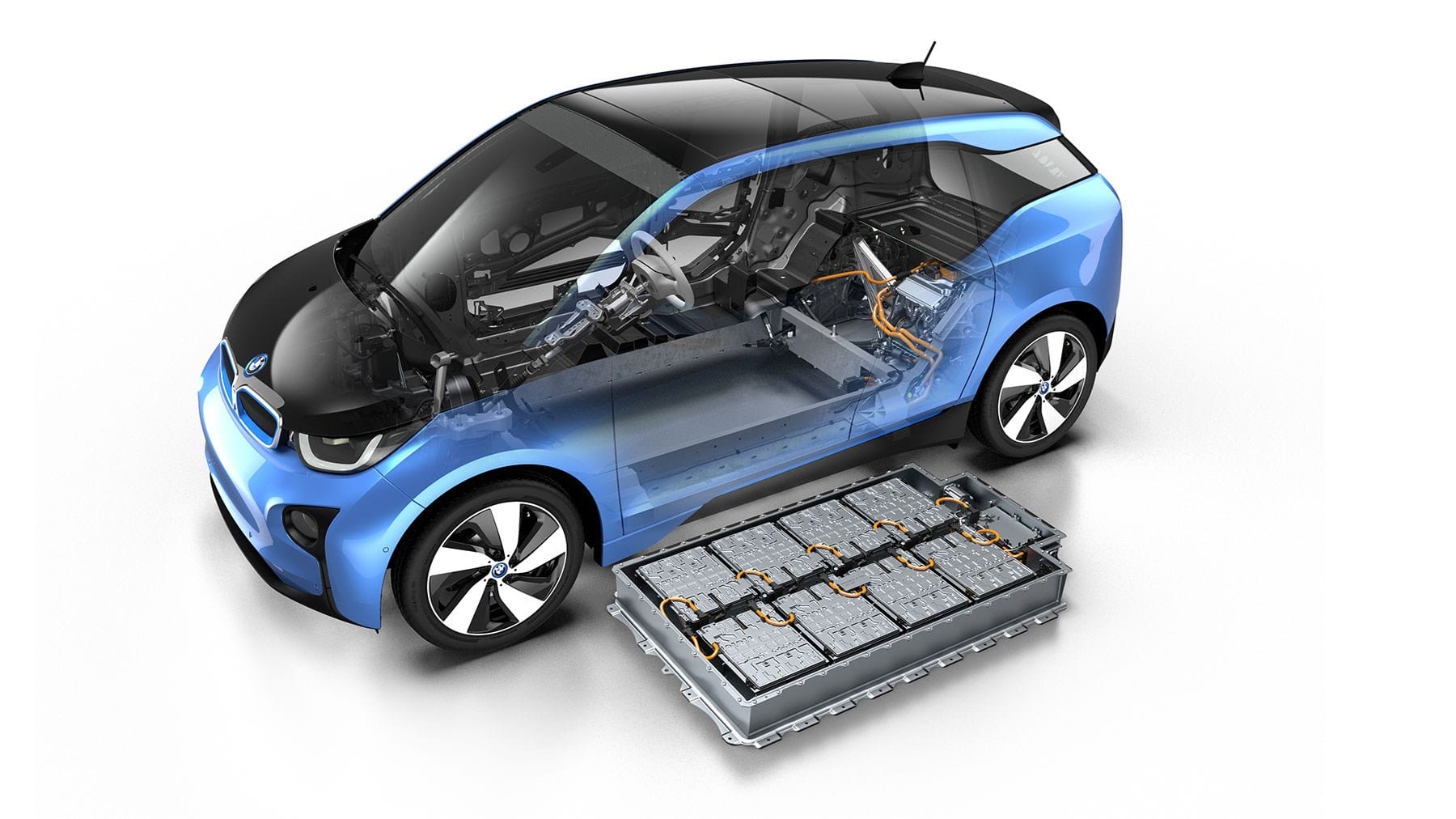

The battery is the heart of any electric vehicle, determining its range, efficiency, charging time, and overall performance.

The development of efficient, long-lasting, and cost-effective battery systems is vital to making EVs more accessible to the mass market.

Currently, the majority of electric vehicles rely on lithium-ion batteries, which offer high energy density and long cycles.

However, challenges such as battery degradation, limited range, long charging times, and high costs must be addressed to make EVs a viable alternative to internal combustion engines (ICE).

As a result, there is a growing need for a highly skilled workforce capable of pushing the boundaries of battery technology and innovating in areas like energy storage systems, materials science, and sustainable production methods.

This article delves into the reasons why battery technology is the most critical area for the e-mobility workforce and the skills required to thrive in this sector.

1. Advancements in Battery Chemistry and Materials Science

The development of more efficient and sustainable battery technologies is essential for the future of e-mobility.

While lithium-ion batteries dominate the current market, significant research is being invested in next-generation battery chemistries, including solid-state batteries, lithium-sulfur batteries, and even graphene-based energy storage systems.

Each of these technologies promises higher energy densities, faster charging times, and improved safety compared to conventional lithium-ion systems.

Key Skills and Expertise Needed:

- Electrochemistry: Professionals with deep knowledge of electrochemical processes, including the movement of ions between electrodes, are vital for improving battery efficiency and stability. Understanding how different materials influence these processes is critical for developing next-generation batteries.

- Materials Science: Battery materials, such as cathode and anode compositions, impact an EV's overall performance. Expertise in materials science helps in identifying and developing materials that are not only more efficient but also more sustainable and easier to recycle.

- Nanotechnology: Some of the most promising advancements in battery technology involve the use of nanomaterials to increase energy storage capacity and speed up charging. Nanotechnology experts will be instrumental in designing batteries at the atomic level for superior performance.

The e-mobility workforce must prioritize the development of specialized roles for scientists and engineers who can innovate in these areas, creating batteries that are not only more powerful but also environmentally friendly.

See: Electric car battery technology

2. Battery Manufacturing and Scaling Production

Even with cutting-edge innovations, the scalability of battery production is a significant challenge.

The current global demand for batteries is skyrocketing, not just from the automotive industry but also from sectors like renewable energy, consumer electronics, and grid storage.

To meet this demand, companies must scale up battery manufacturing while maintaining quality control and sustainability standards.

Key Skills and Expertise Needed:

- Process Engineering: Manufacturing batteries at scale requires efficient and reliable production processes. Process engineers with expertise in scaling up battery production lines, optimizing manufacturing workflows, and ensuring high-quality output will be crucial for companies looking to keep up with demand.

- Automation and Robotics: As battery manufacturing grows in scale, automation will be essential to ensure consistency and efficiency. Professionals skilled in robotics and automated systems will help optimize production and minimize human error in complex assembly lines.

- Quality Control and Testing: Ensuring the safety and performance of batteries is paramount. Quality control specialists with expertise in battery testing, degradation analysis, and failure prevention are critical to maintaining high standards in manufacturing.

In addition to these technical roles, the battery industry needs supply chain managers who understand the complexities of sourcing raw materials like lithium, cobalt, and nickel while addressing concerns about ethical mining and environmental sustainability.

3. Battery Management Systems (BMS) and Software Integration

As electric vehicles become more complex, so do the systems that manage battery performance.

Battery Management Systems (BMS) are essential for monitoring and optimizing battery usage, ensuring safety, and prolonging battery life.

BMS technology monitors temperature, voltage, current, and state of charge, preventing issues like overheating or overcharging.

Key Skills and Expertise Needed:

- Embedded Systems Engineering: Developing BMS requires proficiency in embedded systems, where software is integrated into hardware components to monitor and control battery performance. This involves writing firmware and designing control algorithms to manage battery health.

- Data Analysis and AI: BMS relies on real-time data to make decisions. Professionals with expertise in data analysis and machine learning can help optimize battery usage patterns, predict failures, and increase overall system efficiency. The integration of AI into BMS is expected to play a pivotal role in extending battery life and enhancing vehicle safety.

- Cybersecurity: As EVs become more connected, the risk of cyber-attacks increases. Cybersecurity experts will be crucial in protecting battery management systems from potential threats and ensuring the safety of electric vehicles on the road.

4. Sustainability and Battery Recycling

One of the major environmental challenges posed by e-mobility is the disposal of spent batteries.

While EVs are touted as a greener alternative to traditional vehicles, the extraction of raw materials and improper disposal of batteries can lead to environmental degradation.

As the adoption of EVs grows, developing effective battery recycling solutions becomes increasingly important.

Key Skills and Expertise Needed:

- Sustainability Engineering: Professionals who specialize in the lifecycle analysis of batteries will be vital for reducing the environmental impact of battery production and disposal. This includes understanding how to minimize waste, reuse materials, and improve the recyclability of battery components.

- Recycling Process Design: Engineers who can design efficient and scalable recycling processes will be in high demand. The development of closed-loop recycling systems, where materials like lithium, cobalt, and nickel are recovered and reused in new batteries, is critical for reducing the environmental footprint of EVs.

- Circular Economy Experts: The shift towards a circular economy, where materials are continuously reused, will require professionals who understand the intersection of environmental policy, industrial design, and business strategy. These experts will help design systems that maximize resource efficiency and reduce waste in the e-mobility sector.

5. Workforce Training and Development

Given the rapid pace of change in battery technology, continuous education and upskilling are essential for the e-mobility workforce.

Both technical and non-technical employees need regular training to stay abreast of the latest developments in the field.

Collaborations between industry, academia, and governments will be key to developing training programs that equip professionals with the knowledge and skills required to drive battery innovation forward.

Key Skills and Expertise Needed:

- Technical Trainers and Educators: Professionals who can translate complex scientific and engineering concepts into practical training programs will play an important role in shaping the future e-mobility workforce. These trainers will ensure that technicians, engineers, and managers are equipped with the skills needed to handle the latest battery technologies.

- Learning and Development Specialists: Companies will need L&D professionals who can create continuous learning environments that keep employees engaged with cutting-edge technology, particularly as the pace of innovation in battery technology accelerates.

In conclusion, battery technology sits at the core of the e-mobility revolution, making it the most critical area for workforce development in the electric mobility sector.

From advancements in battery chemistry and scaling manufacturing to optimizing battery management systems and addressing sustainability challenges, a wide range of skills is required to support the growth of electric vehicles.

The e-mobility workforce must prioritize the recruitment and development of professionals with specialized expertise in electrochemistry, materials science, software engineering, and sustainability to meet the challenges and opportunities posed by electric transportation.

By investing in workforce development in these key areas, the electric mobility industry can accelerate its transition to a cleaner, more sustainable future.